When it comes to revitalizing American manufacturing, the national conversation often centers on policy: tax breaks, infrastructure spending, reshoring initiatives, or massive investment in clean energy. These are all critical pieces of the puzzle, but waiting on lawmakers to get their act together isn’t exactly my style—or yours, if you’re reading this.

This guide is about what you, an entrepreneur, a tinkerer, or a community builder, can do now. It’s not about billion-dollar foundries, sprawling refineries, or nuclear power plants—those are noble goals, but way above our pay grade. This is about grassroots, garage-door-up, get-your-hands-dirty real action.

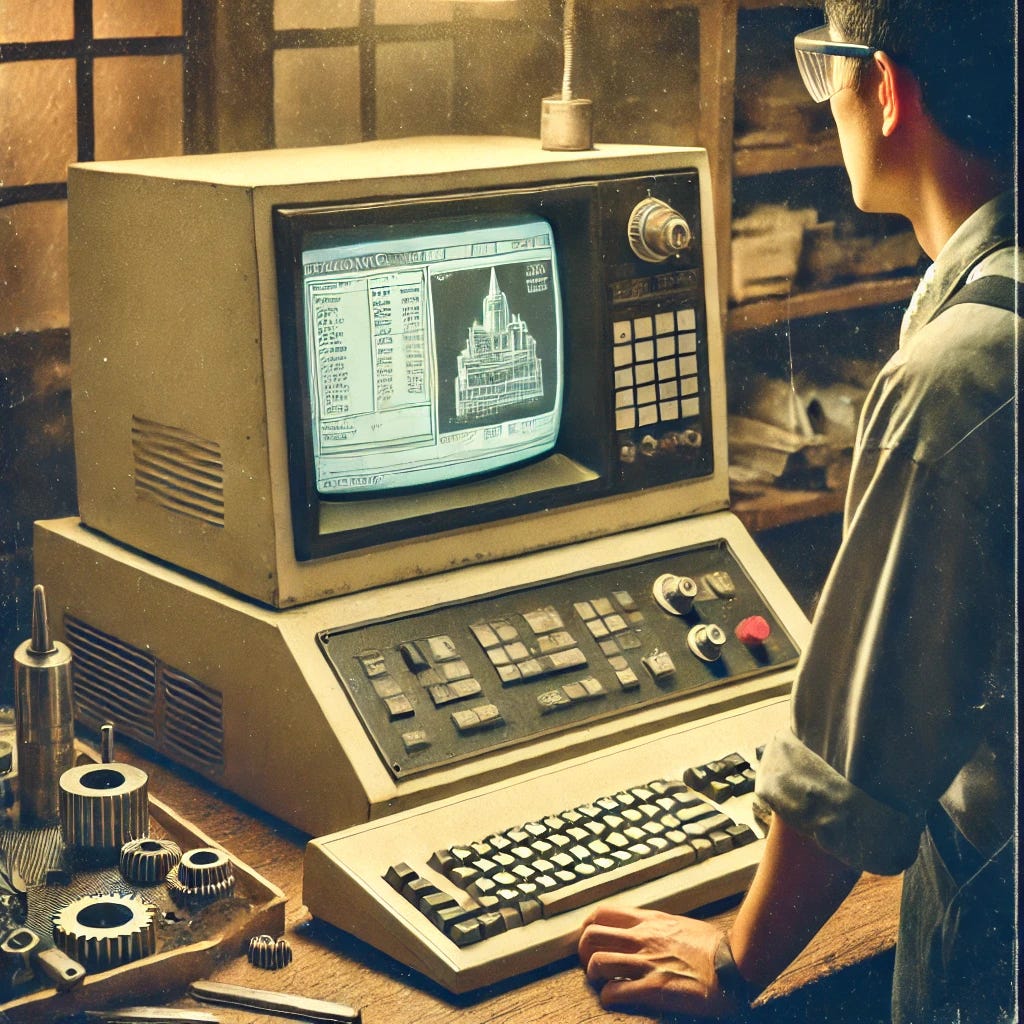

The industrial entrepreneurs of the 1990s—the machine shop owners, the CAD/CAM pioneers, the vinyl cutter operators—showed us what’s possible when technology unlocks access. They didn’t wait for the government to greenlight their dreams, and we shouldn’t either. Instead of lamenting the decline of American industry, let’s bootstrap the reindustrialization of America, one shop, one town, one product at a time.

How the 1990s Created a Wave of Entrepreneurs

The 1990s were a golden era for small-scale manufacturing in the U.S., driven by transformative technologies like CNC (Computer Numerical Control) machines and CAD/CAM (Computer-Aided Design/Manufacturing) systems. These tools democratized production, shifting it from the hands of a few skilled veterans to anyone with the willingness to learn and invest in the tools of the trade.

Example 1: CNC and the Sign Shop Revolution

Back in the day, industries like sign-making were talent-dependent. There goes a story of one guy’s first job at a sign shop run by a guy named Zac, who was a master craftsman. He could hand-paint alphabets by memory on anything—from glass to pickup trucks—with precision. But Zac wasn’t one to rest on his laurels.

When vinyl plotters hit the market, he bought one, opening the door for less experienced staff like me to produce high-quality signs with little more than a PC and some patience. It was transformative. Suddenly, people without decades of training could compete in an industry once dominated by artisans.

This was a double-edged sword for Zac. On one hand, his business faced new competition as other sign shops popped up, even in our small town. On the other, the technology empowered him to grow his business by embracing operational excellence, branding, and service—a combination the competition couldn’t match.

The lesson? Every time new technology lowers the barrier to entry in an industry, it sparks waves of entrepreneurship. The result is more businesses, more jobs, and more innovation.

Example 2: CAD/CAM and the Manufacturing Renaissance

In the late 90s, CAD/CAM systems revolutionized fabrication. No longer did you need a machinist with 20 years of experience to coax precision cuts out of manual equipment. With user-friendly Windows interfaces and reliable GCODE output, a younger, tech-savvy workforce could run state-of-the-art machines.

This innovation unleashed an entrepreneurial frenzy. We’ve heard many stories of machine salespeople striking deals from limos, of shop owners doubling revenue in a year, and of some chaotic “new money” behavior (think crashed Porsches and messy divorces). But the deeper point remains: advanced tools democratized manufacturing knowledge, creating an explosion of small businesses.

The Fall and Rise of American Manufacturing

Unfortunately, the manufacturing boom of the 90s didn’t last. As these businesses scaled, MBAs and CFOs looked for ways to shave costs. Offshoring promised marginally higher profits, and slowly but surely, many industries hollowed out. By the 2000s, the U.S. manufacturing landscape looked bleak.

But there’s good news: the same dynamic that drove growth in the 90s—better tools making entrepreneurship easier—is happening again, and the opportunity is massive.

Why Now is the Perfect Time for a Manufacturing Re-Boom

Generational Transition: Many shop owners who thrived in the 90s are now retiring. They’re not investing in the latest equipment, leaving room for newcomers to fill the gap.

Game-Changing Tech: Today’s manufacturing equipment is leagues ahead of what existed even five years ago. Human/Machine Interfaces (HMIs) are intuitive, CAD/CAM systems are more powerful and easier to use, and equipment is faster, more reliable, and cheaper to maintain.

Accessible Financing: Manufacturers often offer in-house financing to sell equipment, and the terms can be incredibly favorable (think 0% interest or deferred payments). It’s possible to bootstrap a shop with minimal upfront investment.

Practical Steps for Reindustrializing America

Reindustrialization starts small. Here’s how you can be part of the movement:

1. Leverage Manufacturer Financing

Skip the bank loan process and work directly with equipment manufacturers. Companies like Haas, Amada, and others offer attractive financing terms because their goal is to move equipment, not profit off your debt. At the end of a quarter, you might even score 0% interest, delayed payments, or cash-back deals.

This approach is faster than waiting for SBA loans or government programs, and it keeps your equity intact—no need to give up control of your business to venture capitalists who don’t understand manufacturing.

2. Compete on Speed and Service

China dominates on cost, but there are two areas where U.S. manufacturers can shine: speed and service.

Be Faster: Today’s customers don’t want an 8-week lead time. If you can deliver in 5 days while China takes 2 weeks (including shipping), you can charge a premium. The impatience of the modern consumer is your biggest opportunity.

Be Responsive: Answer emails, texts, and DMs immediately. If you’re not awake, hire someone who is. China’s manufacturers often respond to inquiries in minutes. Match that urgency, and you’ll win work.

Put Pricing Online: Take the guesswork out of quoting. Offer instant quotes or at least price ranges on your website.

3. Focus on Heavy, Complex, Custom Work

Don’t compete with China on small, cheap, easily replicable goods. Instead, lean into what America does best:

Large, heavy products that are expensive to ship overseas.

Complex products requiring extensive engineering.

Custom work that requires collaboration between you and the customer.

This is where local manufacturers have an unbeatable edge.

4. Build Cooperatives to Cut Costs

One of China’s biggest strengths is its regional manufacturing clusters, where entire supply chains are localized. While we’re unlikely to replicate that scale immediately, small manufacturers in the U.S. can form co-ops to pool purchasing power for raw materials. By buying together, you can cut costs and compete more effectively.

5. Make Your Operation Scalable and Trainable

Document your processes. Create training manuals, checklists, and workflows. The easier it is to onboard new employees and scale operations, the faster you can grow. A smooth-running, well-documented operation is also easier to sell to investors or pass on to the next generation.

A Call to Action

If you’re reading this, you’re already interested in the future of American manufacturing. The good news is you don’t need to wait for Congress or a government grant to start reindustrializing America. The tools, the financing, and the demand are already there.

By investing in modern equipment, competing on speed and service, and embracing collaboration, we can spark a manufacturing renaissance from the ground up.

It won’t look like the factory floors of the 1950s, but that’s a good thing. It’ll be smarter, faster, more localized, and more adaptable. And best of all, it’ll be driven by people like you.

Let’s get to work.